FlexiCAM GmbH

Booth number: C-L73i

www.flexicam.com

About us

FlexiCAM is one of the industry leaders in CNC Machining technology, specializing in custom-designed 3-, 4-, and 5-axis CNC machining centers. With a robust portfolio of products tailored to meet the demands of complex sectors such as aerospace, automotive, boat building, railways, and more, FlexiCAM has established itself as a go-to partner for companies requiring precise, efficient, and scalable machining solutions. Our machines can handle a broad spectrum of materials, from aluminum and advanced composites to plastics, acrylics, foams, and specialized materials used in model and pattern making.

By combining innovative design with cutting-edge technology, FlexiCAM enables clients to streamline production, improve accuracy, and maximize throughput. We offer both standard machine models and highly customized solutions, ensuring each machine meets the unique needs of our customers. FlexiCAM’s services extend globally, providing pre- and post-sales support to ensure our clients achieve optimum results.

Aerospace Industry Focus: FlexiCAM is particularly renowned in the aerospace sector, where precision, reliability, and adaptability are critical. Our machines are built to manage the intricate geometries and advanced materials frequently used in aerospace manufacturing, including:

High-Speed Machining of Aluminum Structural Components: Ensures quick, precise machining of large aluminum components used in aircraft structures.

Composite Panel and Honeycomb Core Machining: Specialized for Nomex and similar composite sandwich panels, our machines provide the precision required for lightweight, durable aerospace parts.

Advanced Composite Part Trimming, Drilling, and Cutting: Enables the efficient production of high-performance parts made from composite materials.

Aluminum Extrusion Machining: Delivers precise shaping and drilling of aluminum extrusions, essential in creating lightweight yet strong aerospace components.

Pattern, Mold, Jig, and Prototype Manufacturing: Our machines handle everything from pattern and mold creation to jigs and prototypes for testing and production.

Titanium Parts Machining: Handles titanium with ease, offering the durability needed for parts that endure high-stress conditions.

Address

Benkertsweg 9

97246 Eibelstadt

Germany

E-mail: info@flexicam.com

Phone: +49 9303 90810

Internet: www.flexicam.com

P.O. Box 41752

HFZ, Sharjah

United Arab Emirates

E-mail: info@flexicam.com

Phone: +971 6 5263307

Internet: www.flexicam.com

Contact person:

Ashfaq Qadri

Business Manager

E-mail: aqadri@flexicam.com

Phone: +971 50 3686758

Raqeeb Quarashi

Technical Manager

E-mail: rquarashi@flexicam.com

Phone: +971 50 5089986

Products & Services

FlexiCAM specializes in designing and manufacturing top-tier custom CNC Machining Centers, including our renowned line of CNC Routers & Machining Centers. Our team of engineers is adept at tailoring custom solutions to precisely match your unique manufacturing needs.

We cater to a diverse array of industries, notably prioritizing aerospace, boat building, railways, composites, aluminum production, facade fabrication, woodworking, plastics manufacturing, and the sign making sector.

FlexiCAM Piranha

The Piranha is a high-precision 5-axis CNC machining center built for large workpieces, such as patterns, molds, jigs, and prototypes. It’s also widely used in trimming large-scale composite parts, a common requirement in aerospace. Equipped with powerful spindles and capable of working with FlexiCAM’s Advanced Control System (ACS) or industry-standard Siemens and Fanuc systems, the Piranha is engineered for high-speed, precise machining in even the most challenging materials.

With additional options such as multiple gantries, optical (laser) and mechanical probing, palette changers, and advanced dust collection systems, the Piranha maximizes efficiency and accuracy. These features are particularly beneficial in aerospace, where even minor deviations can impact performance and safety.

FlexiCAM Ultimate

The FlexiCAM Ultimate CNC machining center is a heavy-duty machine designed for high production environments, combining robust construction with a single-piece base frame. It’s suitable for both cutting and trimming sheet materials and machining larger 3D objects like molds, jigs, and prototypes. The Ultimate offers a variety of worktable designs, such as durable cast iron tables and the specialized Vilmill vacuum table.

The Ultimate is highly customizable, with options like a 4th axis (tilting spindle) and a 5-axis head, making it adaptable for intricate 3D machining. For demanding aerospace applications, it includes features like linear scales, thermal compensation, and volumetric compensation, which enhance accuracy and maintain tight tolerances.

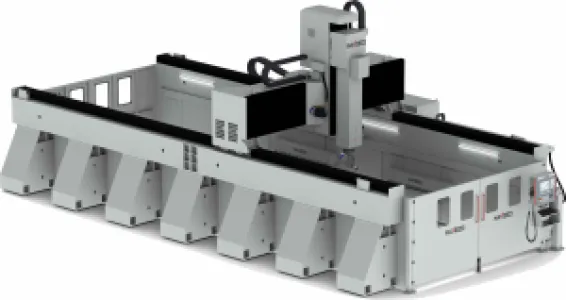

FlexiCAM Xtreme

The FlexiCAM Xtreme is a versatile, large-format CNC machining center with a modular design. It’s ideal for machining large aluminum and composite sheets up to 5 meters wide with virtually unlimited length, making it suitable for sizable aerospace components, and more. Its modular configuration allows customization with additional gantries, enabling simultaneous production across multiple workpieces and significantly increasing throughput.

The Xtreme model supports both Siemens and Fanuc control systems, giving manufacturers the flexibility to integrate their preferred controls. In aerospace manufacturing, it is highly valued for its capability to produce large panels and parts efficiently. Optional features include high-speed spindles, custom tool changers, and multiple gantry systems, allowing companies to scale production without compromising on quality or precision.

FlexiCAM XL

The FlexiCAM XL has been specifically engineered to cater to the needs of high-production shops, and is equipped with powerful AC Servo drive system as a standard feature.

These machines are highly suitable for demanding applications such as machining non-ferrous metal, solid surfaces, and plastic parts. They have been designed to operate in production-type environments and are capable of handling a broad range of manual tool change and automatic tool change spindles to meet specific application requirements.

The XL's foundation is constructed using heavy welded tube on tube design, creating a single, sturdy unit. The machine is customizable with various options available from FlexiCAM, including but not limited to, Rotary Axis, C-Axis, Siemens and Fanuc Controls, I-Cut Vision, Auto Lubrication, and more.

Aluminum Stacked Sheet Machining System

FlexiCAM offers a unique system for aluminum stacked sheet machining, featuring a pressure foot, detagging option, and high-velocity chip extraction. This configuration minimizes debris, optimizes cutting performance, and provides a cleaner work environment.

-thumb.webp)