Northrop Grumman LITEF GmbH

Booth number: C-M78

www.litef.de

About us

LITEF is one of the leading companies in the development and manufacturing of navigation and sensor systems. The company's expertise is based on German technology for mechanical, fibre optic and micro-electro-mechanical inertial sensors. This enables ITAR-free distribution of LITEF products around the globe.

Founded in 1961 and headquartered in Freiburg im Breisgau (Germany), the product range includes sensors, inertial measurement units, attitude and heading reference systems, inertial navigation systems and inertial reference systems. In close dialogue with the customer, specific product solutions are developed for measurement and navigation tasks, with maximum precision and reliability requirements.

LITEF products are in use worldwide with applications ranging from civil and military aviation, land and marine applications to industrial solutions.

Address

Loerracher Str. 18

79115 Freiburg

Germany

E-mail: loforte.tanja@litef.de

Phone: +49 761 49010

Internet: www.litef.de

Products & Services

Our products are qualified and certified to the highest safety standards in the aviation sector, such as DO-178C Level A, DO-254 Level A and DO-160 in commercial aviation as well as the equivalent standards in military aviation. We also offer a wide range of solutions and products for maritime applications.

LLN-GZ - Hybrid Land Navigator is a dead reckoning navigator which receives automatic position updates from GPS - when available. Based on a full six degrees of freedom IMU its design provides state-of-the-art navigation performance by consistently applying the inherent advantages of LITEF’s proprietary MEMS technology

LLN-G2 Hybrid Intertial Land Navigator is the newest generation of hybrid inertial naviator which receives automatic position updates from GPS when available. Based on a full six degree of freedom IMU its design provides a navigation performance matching navigators with more expensive Ring Laser Gyro sensors by applying the inherent advantages of Fiber Optic Gyro technology

LCM-300B magnetometer is a very precise 3-axis strapdown sensor that measures the magnetic field. It determines the direction and strength of the Earth’s magnetic field and transmits this information to the AHRU. The magnetometer works with an input voltage of 28 VDC. The LCM-300B magnetometer transmits its measured values and function status across a serial digital RS-422 data bus with an HDLC log. It is configured for operation in Auto-Send mode to enable the data to be transmitted automatically and continuously after being switched on. The sensor system on the LITEF magnetometer is based on the principle of flux gate technology that has already been introduced in the current LITEF AHRS products. The LITEF LCM-300B magnetometer is a compact unit comprising a magnetic sensor unit, sensing and interface electronics and a 28 VDC power supply with filters.

LCR-100 High precision, outstanding reliability Based on decades of experience with fibre optic gyroscopes and the development of sensors based on MEMS technology, LITEF established its LCR-100 Attitude Heading Reference System (AHRS) on the market successfully. This AHRS based on FOG technology is characterised by light weight, low volume and low power loss, combined with extremely precise sensor data. Furthermore, this system delivers outstanding reliability. The high precision of the sensors used on the LCR-100 facilitates autonomous heading alignment (gyro compassing). This completely eliminates the need to use malfunction-prone magnetic sensors for heading alignment. The LCR-100 can be connected to an external GNSS receiver. In this case, the LCR-100 provides ’hybrid position solutions’ for navigation and flight control. In particular, the LCR-100N variant was designed to facilitate navigation, even during a period of GNSS downtime. The outstanding properties of the LCR-100 Gyro Compass AHRS make this device especially well-suited to applications that require high levels of performance data and safety. The LCR-100 phased out the previous LCR-92 and LCR-93 systems, with its better performance data and extended capabilities. As standard, the data is output in ARINC 429 format with the option of attitude and heading reference data being output using analogue interfaces (e.g. synchro interface). Today, the LCR-100 is used worldwide in turboprops, business jets, IFR helicopters, regional aircraft and in military COTS applications. This product is not only popular with aircraft manufacturers and operators for new installations, but also for retrofits.

LCR-350B Compact, precise and resistant Ultimate safety under the most demanding of conditions Based on MEMS-technology gyroscopes and accelerometers, the LCR-350B AHRS delivers ultimate reliability under the most challenging operational conditions. Intensive research and development at LITEF have given rise to a product that - in a compact housing and with light weight - delivers superlative performance and ultimate protection against high-frequency radiation (e.g. radar). Compared to equivalent systems based on MEMS technology, the LCR-350B provides enhanced precision and resistance to vibration right across the entire operational range. As well as the heading & attitude angle, the LCR-350B outputs physically robust acceleration and rotation data, so it delivers an attractive solution for use in all kinds of aircraft and helicopters. The system obtains its heading reference from an external magnetometer. Whenever GNSS data is supplied to the system, it can also output hybrid navigation data with a high bandwidth and low noise. The LCR-350B outputs its signals across an ARINC 429 interface to the cockpit system and if required, it gives the pilot the option of switching into free inertial heading mode (DG mode). The LCR-350B supplements the existing fibre optic AHRS systems from LITEF and is certified in accordance with ETSO/TSO C-201.

µCORS MEMS rotation rate sensor for diverse applications under the harshest environmental conditions. Robust, precise and compact LITEF’s new family of MEMS gyros includes robust and high-performance angular rate sensors that meet high accuracy requirements even under harsh environmental conditions in industrial, airborne aviation, land or marine applications. Even under high shock loads, the output of highly precise data is guaranteed. Various interface options for the output temperature-compensated angular rates, angle increments or accumulated angles by means of an asynchronous or synchronous interface allow flexible adaptation to a wide range of applications. The µCORS technology allows production of smaller sensors at lower costs than comparable FOG sensors. Thus, the µCORS is particularly suitable for price-sensitive applications in which a small size is required despite high accuracy and environmental requirements.

µFORS For the demanding requirements of land, sea and air applications Small, light and versatile LITEF’s µFORS fibre optic rate gyros were developed for the demanding performance and quality requirements of land, sea and air applications. The µFORS provides compensated angle or rotation rate data to the asynchronous or synchronous digital IBIS interface. With its small size, light weight and low power consumption, the µFORS can be integrated in many applications. The LITEF µFORS cannot be influenced by gravitation and it has no moving parts. This makes it resistant to shock and vibration. It delivers high reliability and requires no periodic maintenance.

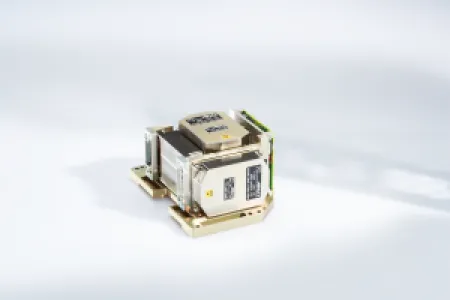

µIMU Inertial measuring unit based on MEMS The perfect measuring unit The µIMU is based on MEMS sensors that we developed in-house. It is a complete inertial measuring unit comprising three MEMS rate gyros three MEMS accelerometers, the associated electronics and power supply, all in a robust, hermetically sealed housing. With its small size, its easy-to-integrate interface and its excellent performance data, the µIMU is the perfect measuring unit for all applications. Attitude-heading reference systems Flight control and stabilisation systems Stabilisation of cameras, antennas and other instruments on mobile platforms

FOG-IMUs FOG-based inertial measuring unit Long life cycle without periodic maintenance FOG IMUS units comprise three gyro axes for rotational measurement, three accelerometer axes for the measurement of linear acceleration, a processor card, a power unit and a housing with connectors and other mechanical components. Other configurations are possible and can be developed easily on the basis of the modular inertial sensor concept. The advantage of FOG technology is that individual requirements can be satisfied easily and quickly. Missile guidance Vehicle guidance Stabilisation of platforms Solutions for systems with stringent requirements – such as navigation and attitude-heading reference systems – are achieved through the integration of navigation software and the connection of GPS to the IMU. Free of moving parts, FOG IMUs are resistant to shock and to high levels of vibration. They are extremely reliable and have a long service life without periodic maintenance which reduces life cycle costs.